CADILLAC BIG MEET 2023 - THE MOVIE

One of my many tasks is to do the website, photography, the videography and promotion for this event. We are a great team of friends and enthusiast and enjoy organising this event.

This year we had a very hot summer weekend and 101 Cadillacs attending the event.

This year my wife and I took the 67 Eldorado and the 78 Biarritz to the event. During the 3 days there we shot a TV report and the official aftermovie, which can be seen here! Enjoy.

It's best viewed on a large screen in 4k resolution.

The official aftermovie

We also did a TV report for an Austrian TV-Channel.

We do not know yet when the next event can take place - I hope in 2025. Check the Cadillac BIG Meet website for updates- as soon as we have more info the website will be updated.

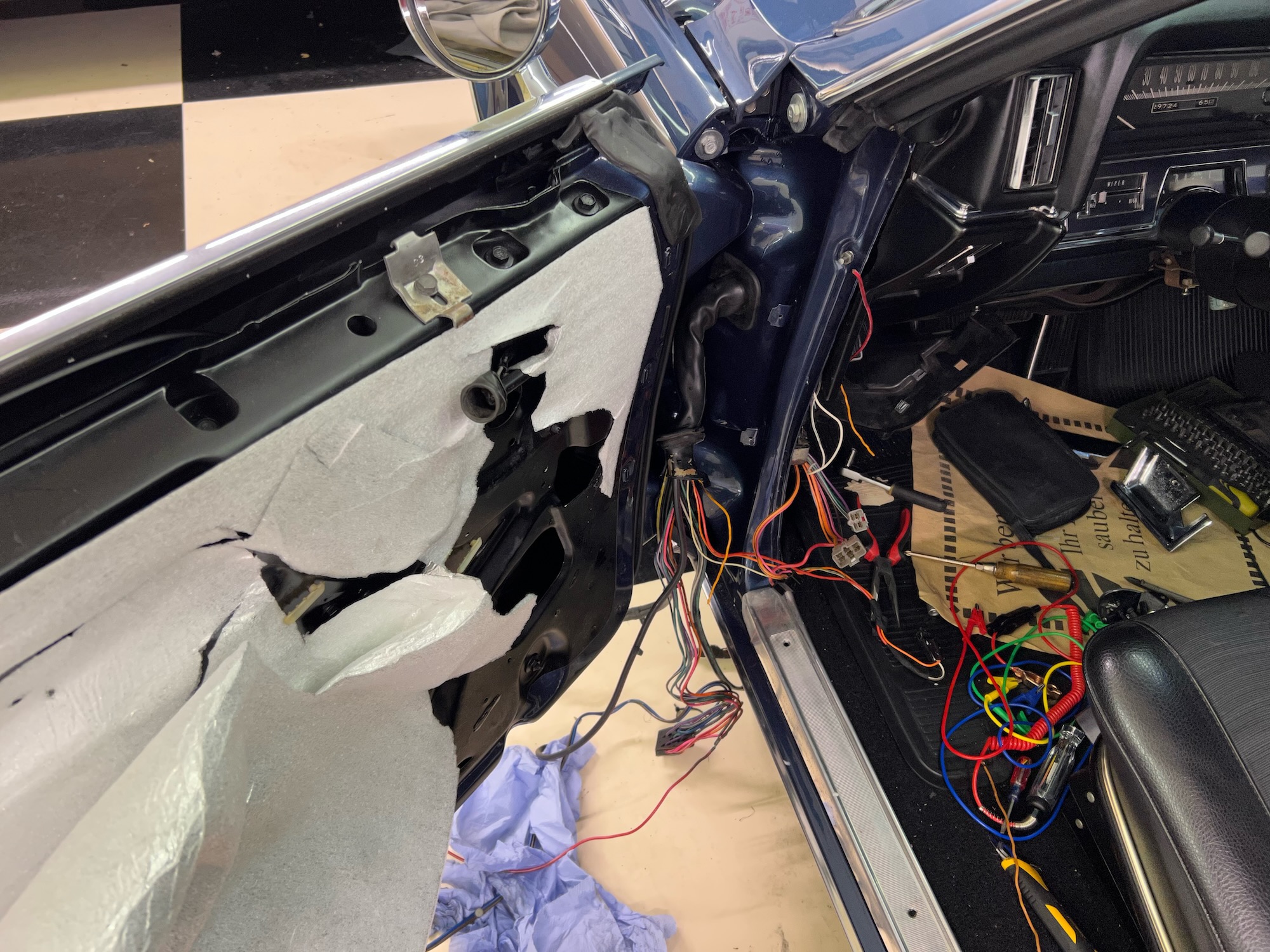

1967 ELDORADO BROKEN POWER WINDOW CABLE

Details coming soon!

CADILLAC BIG MEET 2023 PROMOTION

My wife and I shot a short promotional video with some team members to highlight the program for this years event:

1978 CADILLAC ELDORADO HEATER CORE REPLACEMENT

SPRING CLEANING THE 1967 ELDORADO

Unfortunately its very rainy and I can't test drive it.

Here is a short video.

CADILLAC BIG MEET 2023

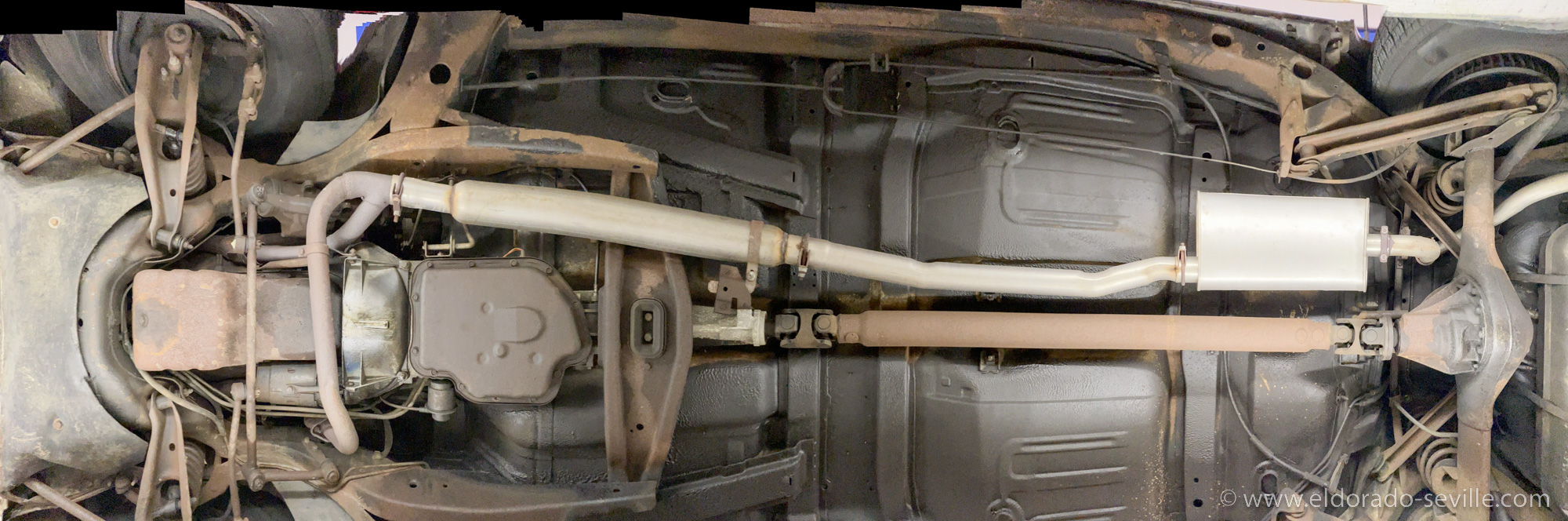

THE 1966 UNDERCARRIAGE PROJECT - LONG POST!

VIDEO RECAP

I did not plan to do a video about the restoration, but here is a short collage of some footage I had: (on youtube you can watch it in 4k HDR

This is a short video showing what was done

BEFORE

Some "BEFORE" pictures showing how the car looked before I started working on it.

AFTER

This is how it looks now - after all the work I did. Click to see the full report.

READ MORE...

THE CADILLAC GRAND EUROPEAN MEETING - I WON A SPECIAL AWARD & WE SHOT A MOVIE

We were asked to do a film for them. We took our Persian Lime 1974 Coupe deVille to get there. It has been a 1100 miles round trip for us during an intense and unusual heat wave with temperatures around 37°C (100°F). The 74 performed flawlessly.

I feel very honoured that my car got a special award from "Honest" John Foust - "The Texan´s Choice Award" where he selected his personal favourite car. Below is a video of the award ceremony, where John explains why he chose my car:

The award ceremony

The event was just great with some awesome cars attending. The quality of cars is getting higher and higher every time.

Thanks to Klaus Deisinger, Sigrid Hoffmann and Christian Doerk and the rest of the team for organising this great event.

We started editing the video after each day on location to be able to show a highlight video at the gala night on Saturday night. Quite a task…

Here is the teaser we showed that night:

The teaser video

A few days after the meeting the full movie was published which can be viewed through the Classic Cadillac Club Deutschland e.V.

The full movie!

My wife Afra filming.

Editing on location

Nice view during work

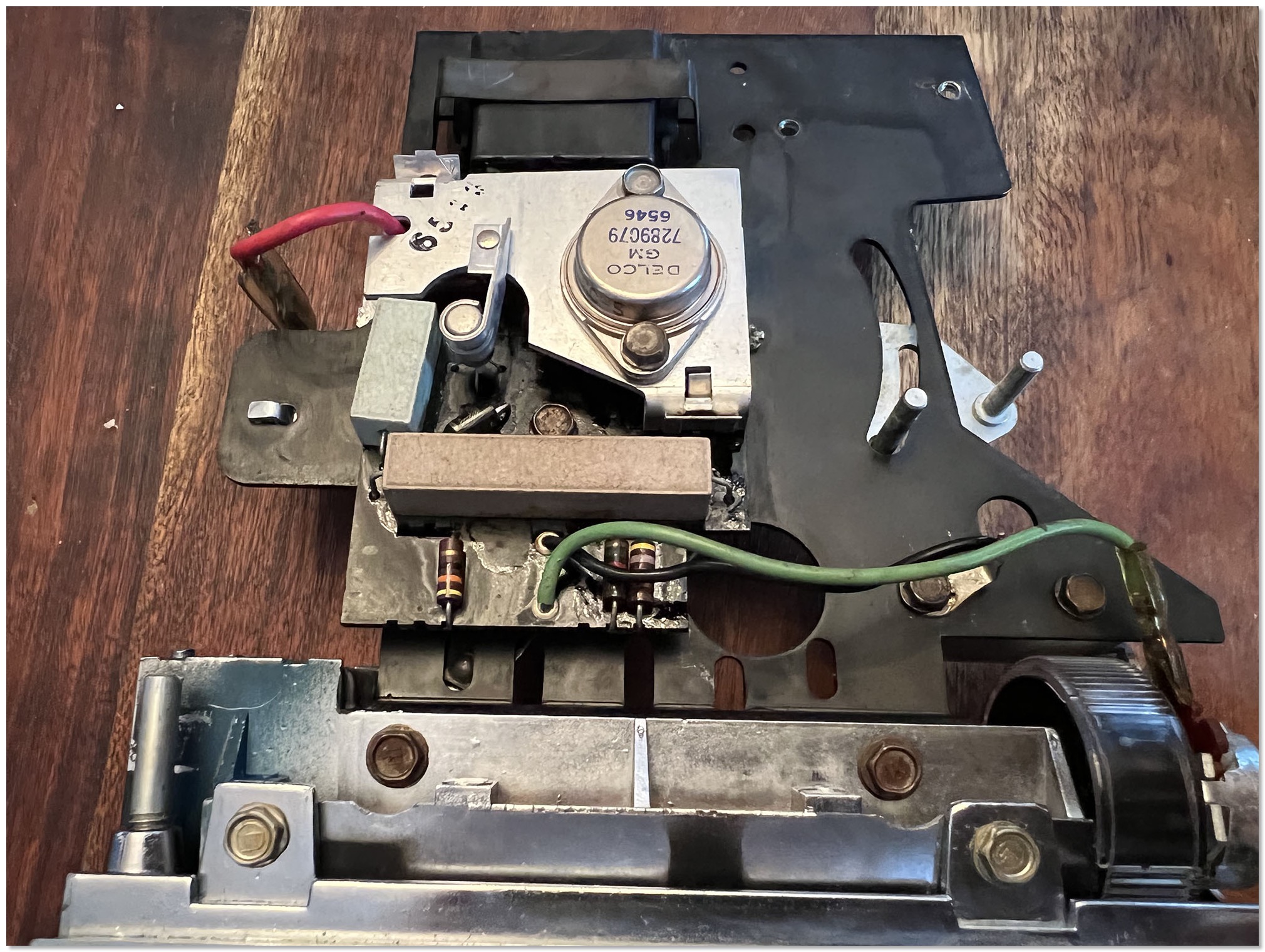

1966 AC BLOWER VACUUM MASTER SWITCH

I rebuilt the carburetor and let the car idle for a while. During this I wanted all accessories to move and also turned on the heat. It came on as always and after about 30sec the blower went off again. The power servo started to move in and out all the time by itself, but the blower would stay off. The idle speed up came on and off as well depending on the placement of the power servo. After a while it stopped doing this and stayed in the fully retracted position (full heat). If I turned the temperature dial it did not change anything - but it was around freezing outside and this is what it should, do as the sensors sense the low temperatures and then send the system into full heating mode.

I checked the following things.

- Master Switch seemed to work and gets engaged by vacuum. Power is going through it as it should. Current is going in and out. (This is what I thought…)

- Blower Motor tested with a direct feed - worked

- Blower Motor Relay - tested. Put a 12 V feed to the dark blue connector and it engaged and the blower motor came on. There was no current coming through the blue wire though.

- Power Servo - cleaned all contacts and measured the resistance in all positions - looked good to me

- Control Head in Dash - removed it and checked the blower switches - it seemed to work.

Full vacuum was applied to the power servo, and I also checked the vacuum and voltage at the transducer. I also checked all vacuum actuators with a vacuum gauge, but everything checked out perfectly.

I then put everything back together. Still the system did not work in the full heat position. I did a lot more tests and checked the vacuum and electrical diagrams.

I ordered the 1966 AC manual from "Cadillac Tim" which is available also on ebay for $45,- . These instructions are a must-have for your car, as everything about the AC system is explained very well by Tim. There is a great troubleshooting guide in there. Its money well spent! Tim also offers a rebuild service for many Cadillac parts and has a great selection of refurbished parts. Check out his website!

The 1966 dash control unit - here you can see the amplifier part.

After days of troubleshooting it finally dawned on me where the problem was. I had checked the master vacuum switch multiple times and when checked it always had electrical continuity. But I did not check it correctly. I only pushed the backside of the switch until I heard a click.

I should have tested it with full vacuum applied. As it turned out, if high vacuum was applied to the switch (during heating mode), the switch did no longer work correctly!

The contacts did no longer touch when full vacuum was applied to the switch…

The contacts did no longer touch when full vacuum was applied to the switch…

Today I took it apart and made a video about it. As it turned out the switch contacts did not align as they should and I had to bend it a little bit to make it work again. I then put everything back together and now the AC system works perfectly again. Check out the video for all the details!

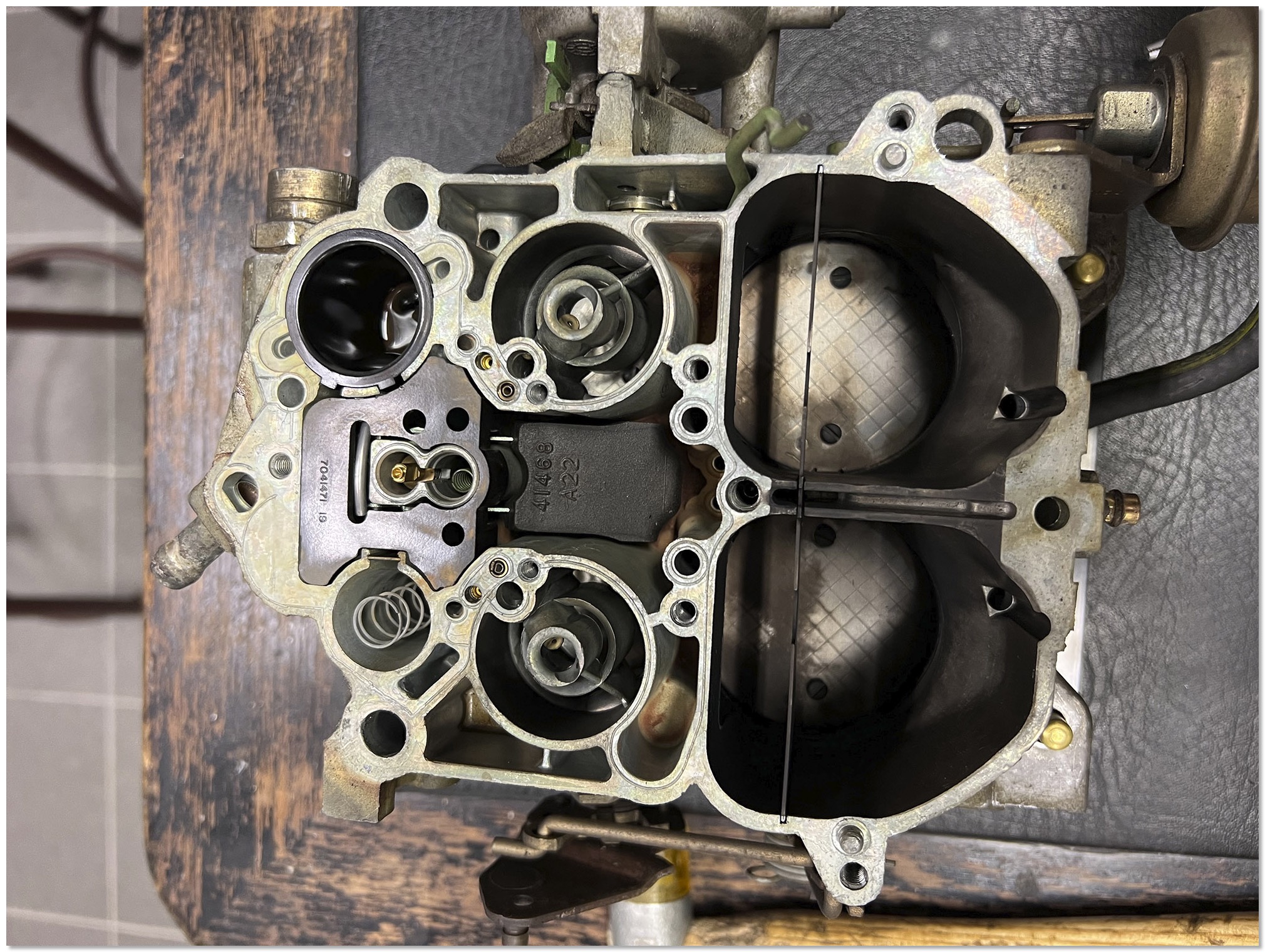

1978 ACCELERATOR PUMP REPAIR

The car would have a slight hesitation for one or two seconds when driving away from standing still and idling. The hesitation was not present at any higher speeds - only when starting from standing still, no matter how hard I hit the pedal.

Once the car was rolling, it ran perfectly. 2 or 3 times the engine even stalled in the past.

That's why I suspected the accelerator pump.

Replacing it is not too difficult. You basically only need a rebuild kit and remove the carburetor from the car. Then you have to remove 8 screws to take the top off and remove 2 linkages. I'm not a carburetor expert at all, but luckily my friends ,who did the job before, helped me, but it really is not difficult at all. I found some great how-to video on YouTube on how the Quadrajets are taken apart and back together - They have some very informative videos on their youtube channel - here is one of them:

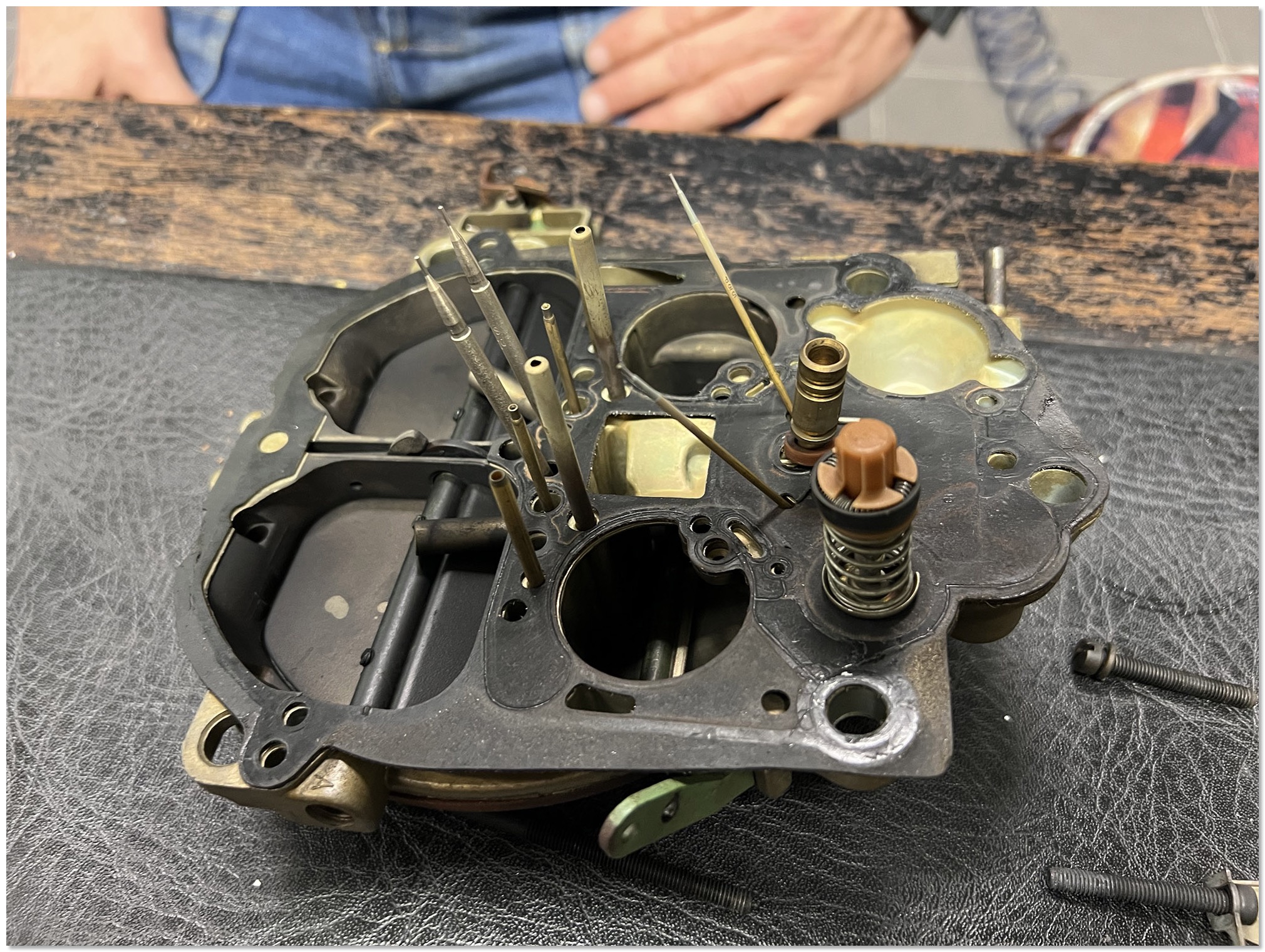

The Quadrajet after removal.

The Quadrajet after removal.

The Quadrajet with the top removed The accelerator pump on the right side

The accelerator pump on the right side

My friends Steve and Lucky helped a lot. Thanks my friends! We did all the work in Luckys fantastic garage and shop.

We had "Carburetor Monday" as everybody was working on their carburetors.

We had "Carburetor Monday" as everybody was working on their carburetors.

We replaced the pump rubber and put everything back together. The carburetor looked very clean inside with only minor deposits, so we left everything else as it was.

I can't wait to install it back into the car and hope the problem is fixed - did not do a full rebuild as it is still very clean and nice inside. Only installed new rubber on the pump and new top gaskets. Hopefully the problem is fixed now. I will update the page once the carb is back in the car.

1966 HOT CHOKE CARBURETOR REPAIR

I removed the choke housing from the car and it was completely stuck and did not move at all. Both the lever and the counter weight were completely frozen up although everything inside the housing looked pretty clean.

First I tried anti seize oil which did not change anything. Then I soaked the unit in a parts cleaner solution over night which did not free it up either. The next day I soaked it in a rust removing solution which did not help either. I then put it in a can of transmission fluid for a while.

In-between I always gently tried to move it and suddenly it freed up and now works perfectly smooth again. I put the carburetor back together and now the car is very easy to start again - even on a very cold day.

The choke after repair. The choke mechanism disassembled for repair after I managed to free it up.

The choke mechanism disassembled for repair after I managed to free it up.

1967 ELDORADO CARBURETOR REPLACEMENT

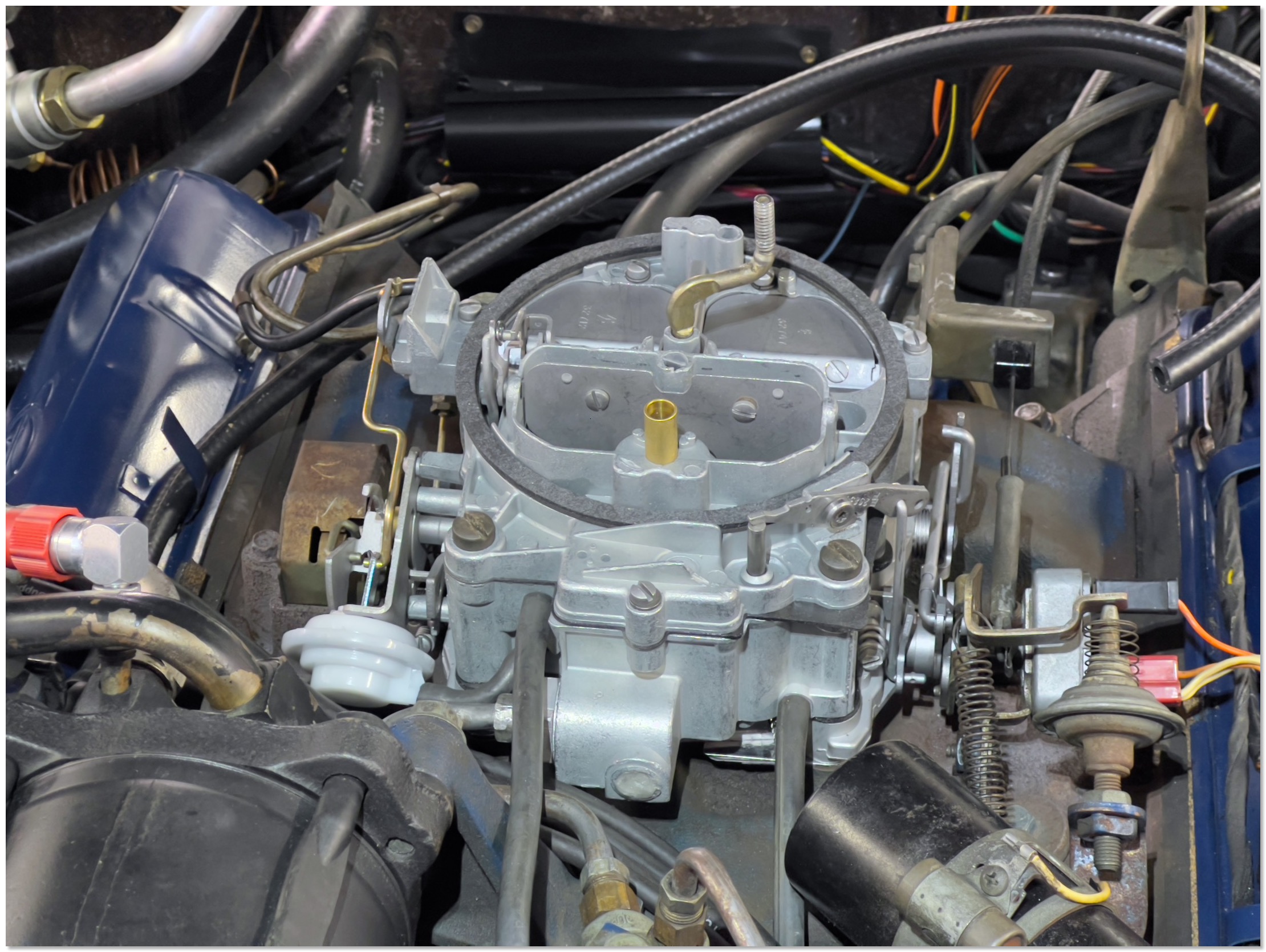

The Eldorado now purrs like a kitten again with its new Quadrajet. I now have two more carburetors to do - the 1966 has a stuck choke and the 1978 needs a new accelerator pump.... The video is also available on YouTube in 4K HDR quality...

I took a short video of the installation process.

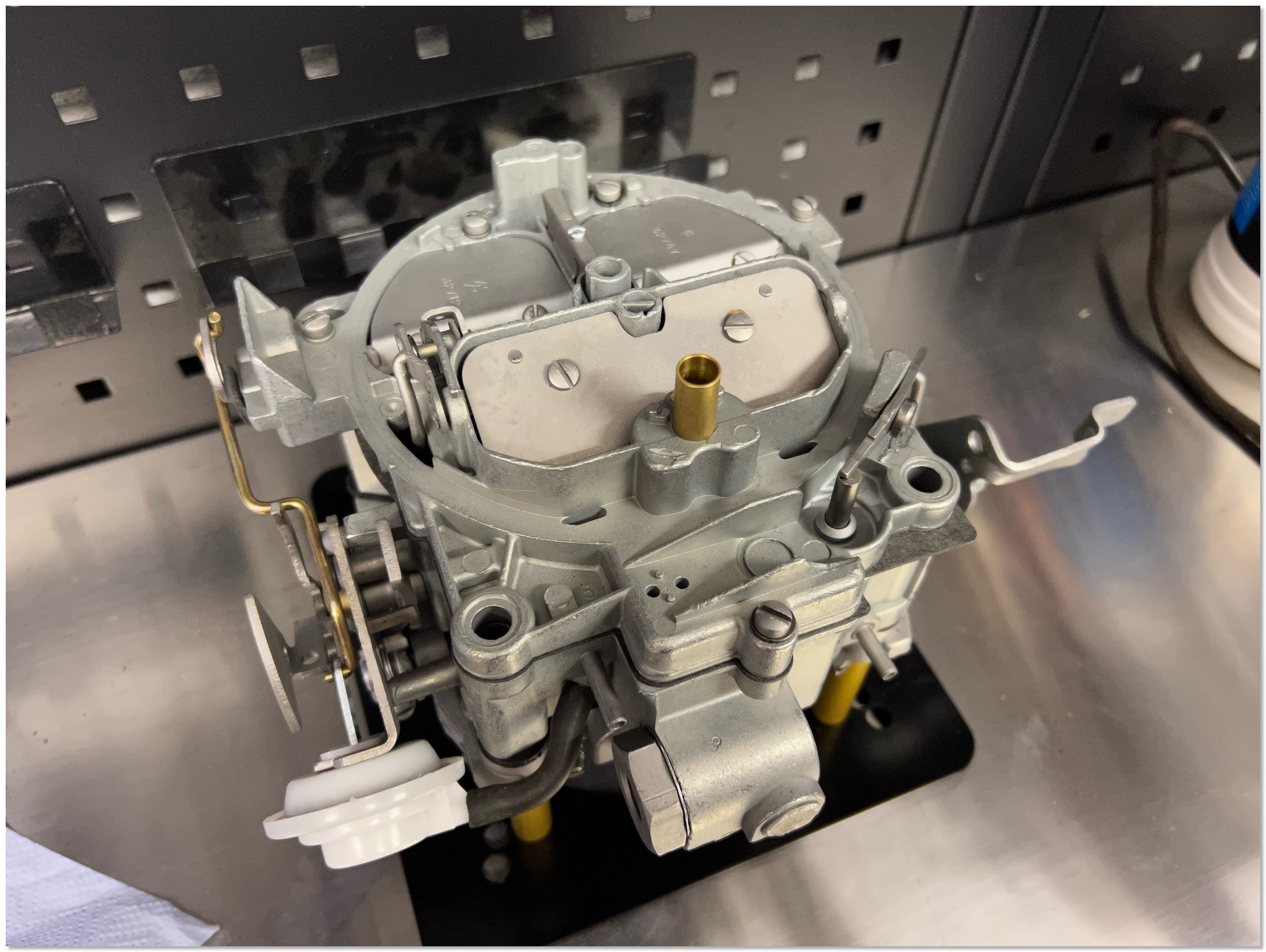

The rebuilt Quadrajet on the bench.

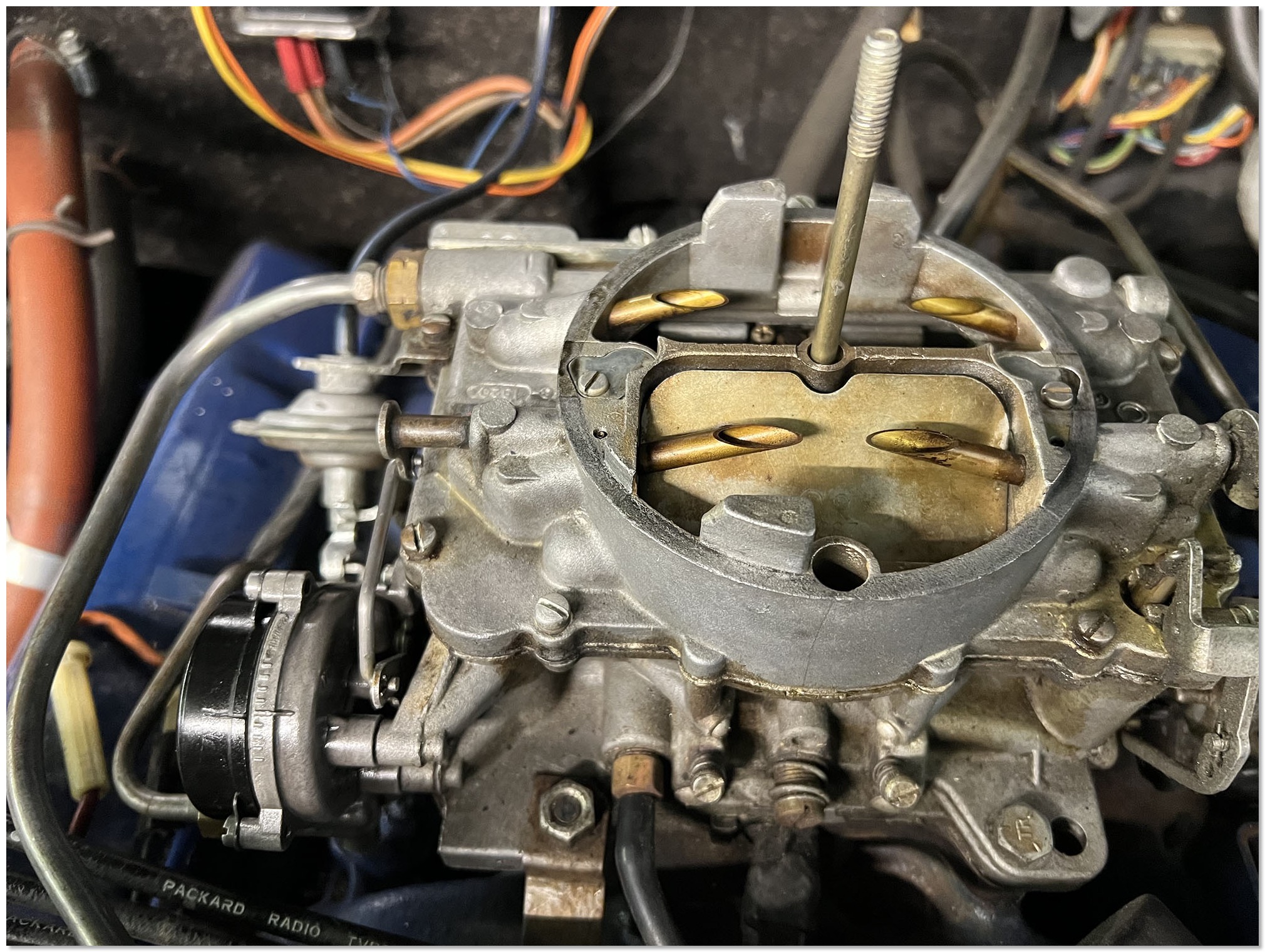

The old original 1967 Eldorado Quadrajet - this is the non California version.

The rebuilt Quadrajet installed.

1966 Cadillac Coupe deVille (15)

1967 Cadillac DeVille (54)

1967 Cadillac Eldorado (71)

1971 Lincoln Continental Mark III (23)

1974 Cadillac Coupe deVille (45)

1978 Cadillac Eldorado Biarritz (24)

1996 Buick Roadmaster (19)

Car Shows (53)

Cruising (4)

For Sale (3)

Garage Stuff (32)

Pacer (1)

Restoration (137)

Various (55)

Video (16)

Website News (30)

- 6 way power seat

- 8-track

- 10 Ohm

- 429

- 1932

- 1957

- 1958

- 1958 Cadillac Eldorado Seville

- 1958 Cadillac Repair Tip

- 1959 Cadillac Eldorado Seville

- 1964

- 1965

- 1966

- 1966 Cadillac Coupe deVille

- 1966 Cadillac Repair Tips

- 1967

- 1967 Cadillac DeVille

- 1967 Cadillac Eldorado Repair Tip

- 1967 Cadillac Repair Tip

- 1967 Eldorado

- 1968

- 1970 Cadillac Eldorado

- 1971

- 1971 Lincoln Continental Mark III

- 1974

- 1974 Cadillac Coupe DeVille

- 1974 Cadillac Repair Tip

- 1976

- 1977

- 1978

- 1978 Cadillac Eldorado Biarritz

- 1978 Cadillac Repair Tip

- 1980 Cadillac Eldorado Biarritz

- 1996

- 2012

- 2014

- 2017

- 2018

- 2019

- 2022

- 2023

- 3063206

- 7027235

- 7800483

- 7805675

- 7805676

- 12355706

- 17058531

- 17059968

- 17059969

- 22010515

- 22010661

- A.I.R

- A6

- AC

- AC Compressor

- AC Electrical Diagram

- ACC

- Accelerator Pump

- Accelorator pump

- Actuators

- Adriatic Blue Metallic

- Ads

- Aftermovie

- Air Pump

- Aircondition

- AIRPUMP

- ALC

- Alternator

- AM

- AM-Transmitter

- Antenna

- Anti Rattle Clips

- Antique Gold

- Arizona Vintage Parts

- Arrival

- Article

- ASC

- Ash Tray removal

- ATC

- Atlantis Blue Firemist

- Austria

- Austro Classic

- Autolite SP-459

- Automatic Seat Back Release

- Award

- Banner

- Barn Find

- Battery

- Battery Tray

- Beach Race

- Bearing

- Bendix

- Biarritz

- Bigfoot

- Bill Hirsch Engine Enamel

- Bleeder Screws

- Blower

- Bolts

- Borg

- Brake Booster

- Brake Fluid

- Brake Gray

- Brakes

- Broken Bolt

- Brougham

- Bucket seats

- Buick

- Bumper End

- Bushings

- Cadillac

- Cadillac BIG Meet

- Cadillac BIG Meet

- Cadillac birthday cake

- Cadillac Blue

- Cadillac Color Selections Dealer Book

- Cadillac Coupe deVille

- Cadillac Dealer

- Cadillac Meeting

- Cadillac Mini Meeting

- Camaro RS

- Caorle

- Car Show

- Carburetor

- Card

- Carpet

- Carter AFB

- Cavalry Twill Vinyl

- CB

- CBM

- CCCD

- Choke

- Christmas

- Citizens Band

- Classic Cadillac Club Deutschland

- Clay Towel

- Cleaning

- Clock

- Clockwork

- Clutch

- Clutch Coil

- Collector

- Colonial Yellow

- Color Coded Springs

- Commercial

- Compound

- Compressor

- Condenser

- Continental Mark III

- Control Head

- Conversion

- Convertible top

- Coolant

- Corona

- Cowl

- Cruise Control

- Cruising

- CV Boots

- CV JOINTS

- D6230

- Dash Trim

- Decal Removal

- Decals

- Decoration

- Dehumidifier

- Delco Moraine

- Der Standard

- detailing

- Deville

- Diagnosis Chart

- Diagram

- Dial

- Digital Rotary Drum Clock

- Diner

- Disc Brakes

- Distributor

- Diverter Valve

- Door Jamb Switch

- Door Rubber Conduit

- Dornbirn

- Dot3

- Drive Shaft

- Driving tour

- Drum brakes

- Dry Ice Blasting

- Dry Ice Cleaning

- DVD

- Eastwood

- Eldorado

- Electric Choke Thermostat

- Electrical schematic

- Elvis

- Engine Bay

- Ep

- Epoxy floor

- Europe

- Evaporator

- Exide

- Factory Markings

- Fender Skirt

- Floor

- Flushing

- Foam

- For Sale

- Front AXLE

- Front brakes

- Front bumper filler

- Front Floor

- Front wheel bearing

- Fuel Filter

- Fuel Pump

- Fuel Sending Unit

- Fusible Link

- Garage

- Garage Cabinets

- Gasket

- GE

- Gear indicator

- General Time

- Glove box light

- Grand European

- H4

- Haus of Hot Rod

- Headlight Actuator

- Headlight doors

- Headlights

- Heater Core

- Heater Hose

- Heater Valve

- High Idle

- Holley

- Honest John

- Hood

- Hood Emblem

- Hood Ornament

- Hose Clamp

- Hot Choke

- Hot Water Valve

- HotRod

- How to

- Hödlmayr

- Ignition Diagram

- Illuminated Entry

- John D‘Agostino

- John Foust

- Klassikwelt Bodensee

- Kremsmünster

- LaSalle

- Leather seats

- Light Switch

- Limited

- Lincoln

- Lincoln Mark III Repair Tip

- Low Mileage

- Magazine

- Marilyn Monroe

- Mark III

- Master Cylinder

- Master Switch

- Master Vacuum Switch

- Media Blasting

- Meeting

- Meguiras

- MK II

- Mobile

- Model

- Moldings

- Mom

- Mopar Nationals

- Mostkost Kustom

- Movie

- Neon

- NOS

- Oberösterreicher des Tages

- oilchange

- ORF

- Overspray

- Pacer

- Paint

- Paint correction

- Paintjob

- Part Number

- Parts

- Patch Panel

- Perfect Circle

- Permabag

- Persian Lime

- Photo shooting

- Photoshooting

- Pictures

- PinUp

- POA Valve

- Power Antenna

- Power Servo

- Power Vent Windows

- Power Window

- Printed Circuit Board

- Programmer

- Pulley

- Quadrajet

- Quarter Panel

- Quartz Conversion

- R134

- Radiator

- Radio

- Rattle

- Rear brakes

- Rebuild

- Recalibrate

- RediRad

- Reed Switch

- Relais

- Relaunch

- Removing Overspray

- Repaint

- Repair

- Restoration

- RIP

- Roadhouse

- Roadmaster

- Rochester

- Rocker Arm Cover

- Rocker Panel Extension Clips

- Rostio

- Rotary Valve

- Rotterdam

- Rupes

- Rust removal

- Rust removal gel

- Sabre Wheels

- Sand Blasting

- Sandblasting

- Screed

- Season Greetings

- Seasons Greetings

- Seat Back Locks

- Seat Padding

- Seat Transmission

- See through ornament

- Self adjusters

- Sepp's Garage

- Seville

- Sheetmetal

- Shocks

- shop manual

- short

- Sign

- Solenoid

- Spark Plug Wire Routing

- Speakers

- Special Award

- Speed Bleeder Screws

- Splash Guard

- Starter Diagram

- Starter Motor

- Steering Column

- Storage

- suction throttling valve

- sunroof

- suspension

- Swirl Mark removal

- Switzerland

- T3

- Taillight Cover

- Texan´s Choice Award

- Thermostat

- Tilt and Telescope

- Time capsule

- Tomsclub

- Torque Specifications

- Tower Hose Clamp

- Towtruck

- Transducer

- Transmission

- transmission control selector

- transmission control selector indicator light

- transmission shift indicator

- Treadle Vac

- Treffen

- Tri-Band

- Troubleshooting

- Trunk Cardboard Kit

- Trunk lining

- Trunk to bumper cover

- Turn Signal Switch

- TV

- Typisierung

- Ultimate Garage

- Underbody

- Undercarriage

- Undercoating

- Undercoating Removal

- Vacuum Booster

- Vacuum diagram

- Vacuum hoses

- Vacuum Master Switch

- Vacuum Schematic

- Vacuum Valve

- Valve Cover

- Various

- Vent Window Switch

- Vibration

- Vibrator

- Vicodec roof

- Video

- Vinegar

- Vinyl Roof

- Visitor

- Washer Fluid Float

- Washer Fluid Low Level Indicator

- Water Pump

- Wax

- Weatherstripping

- Website News

- Westclox

- Wheel Bearings

- Wheel Housing

- Wiesbaden

- Windlace

- Winter

- Wiring

- Wiring Diagram

- Wonderbar

- Workbench

- Zurzach

GERALD´S CADILLACS - NEWS

GERALD´S CADILLACS - NEWS